Project Portfolio

“Explore a selection of our engineering design, analysis, and fabrication projects, showcasing our expertise in CAD modelling, FEA/CFD simulations, piping, HVAC, and industrial system design.”

01

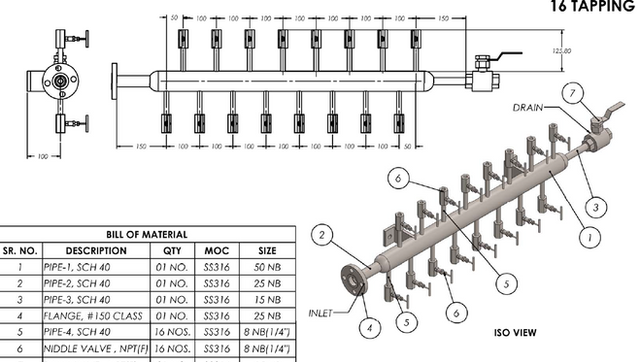

Pressure Reducing System (Hot Water)

This project involved the design and development of a pressure reducing system for hot water applications. The system was engineered to ensure safe, stable, and efficient pressure regulation in industrial piping networks. Key components included safety valves, pressure gauges, reducing valves, and flanges, all integrated into a compact and reliable piping assembly.

Our work focused on precision design, fabrication detailing, and validation of the pressure system to meet stringent safety and performance standards. This project highlights our expertise in piping design, pressure management, and system optimisation for industrial applications.

02

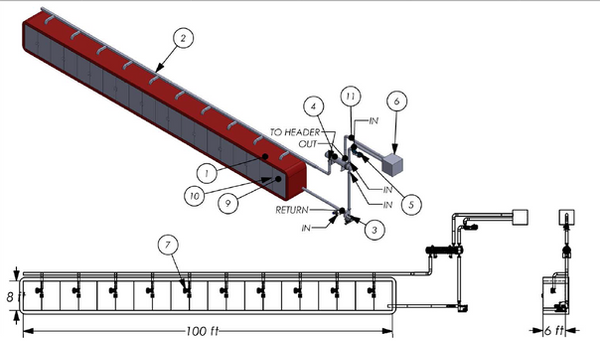

PUFF Heating Chamber

This project focused on the design and development of a PUFF heating chamber for industrial heating processes. The system was created to provide uniform heat distribution across a 100 ft chamber, ensuring consistent performance and high energy efficiency.

The design integrated a complete piping network, return lines, siphons, and valves, engineered for safety, reliability, and operational ease. By combining detailed 3D modelling with practical engineering knowledge, the chamber was optimised for both thermal efficiency and structural integrity.

03

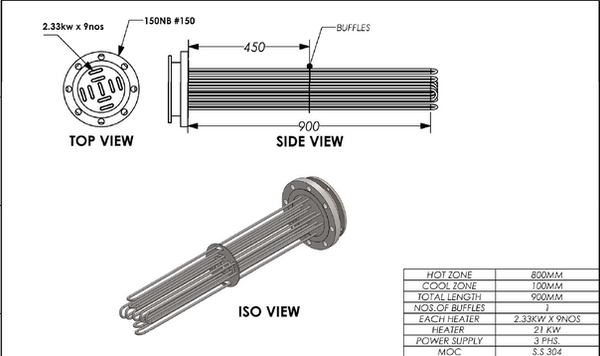

21 kW Electric Heater Assembly

This project involved the design and assembly of a 21 kW industrial electric heater. The heater was developed with multiple heating rods and strategically placed baffles to ensure effective heat transfer and uniform temperature distribution.

Detailed 2D and 3D modelling was carried out to produce a design that is efficient, safe, and fabrication-ready. With precise dimensioning, material specifications, and electrical considerations, this heater system was engineered for long-term durability and optimal performance in demanding industrial environments.

04

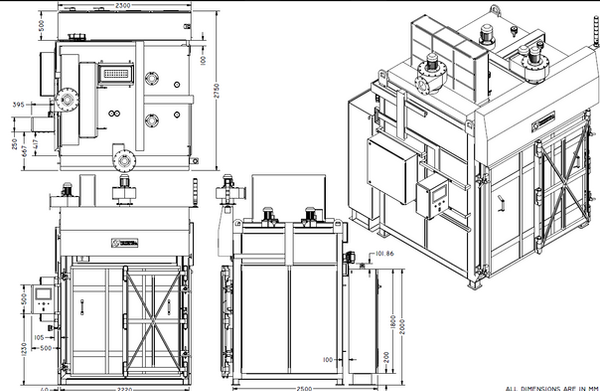

Industrial Oven & Hot Oil Heating System

This project involved the design and development of an industrial oven with an integrated hot oil heating system. The system was created to deliver high thermal efficiency, even heat distribution, and long-term durability under demanding operating conditions.

The design process included 3D modelling, detailed fabrication drawings, and component integration for heaters, insulation panels, and piping connections. Careful attention was given to safety, ease of maintenance, and compliance with industrial standards.

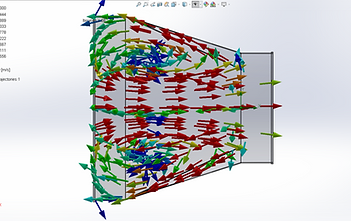

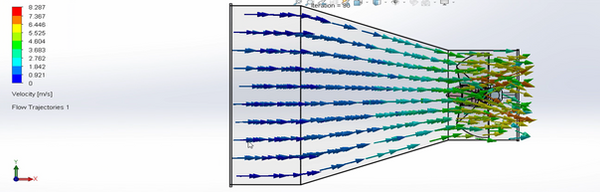

05 Hydro Turbine Diffuser Optimisation (CFD Simulation)

This project involved the optimisation of a hydro turbine diffuser using Computational Fluid Dynamics (CFD). The objective was to enhance turbine efficiency by reducing energy losses through improved diffuser geometry.

Advanced simulations were carried out in ANSYS Fluent, analysing flow characteristics, pressure distribution, and turbulence behaviour. Comparative studies between baseline and optimised designs demonstrated significant improvements in energy recovery.

This project was recognised with a university award and showcased at a research poster presentation.

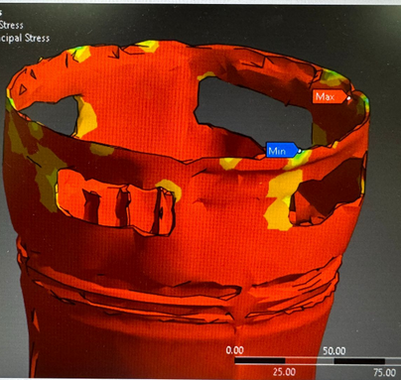

06 Sustainable Urban Drainage System (SUDS) FEA

This project focused on the design and development of a Sustainable Urban Drainage System (SUDS) to manage stormwater efficiently and support environmental sustainability.The modular crate-based design was created in SolidWorks, followed by validation using FEA and CFD simulations to ensure structural strength and efficient water flow. Laboratory testing was carried out to compare physical and digital results, ensuring accuracy and reliability.The project demonstrated innovative engineering for sustainability, durability, and performance in civil infrastructure applications.